Regal gloss in digital printing: sedak presents its new technology

With its new digital printing technology, sedak can now put precious metals onto glass. The interplay between glass, gold and silver creates glass panes with fascinating optical effects – as insulating and safety glass, even curved. Especially impressive: the printing process allows for extremely fine details and filigree structures. Complex design ideas can be realized with high precision.

Two materials that have fascinated mankind for centuries are gold and glass. The elegant radiance of the precious metal and the high value associated with it combined with the bright transparency of the fragile material glass results in a unique and very unusual effect. Sedak (Gersthofen) has made this splendid symbiosis a reality and now prints glass panes of up to 3.30 x 18 meters with genuine gold and silver – with the highest precision and a resolution of up to 1024 dpi.

The printing takes place on float glass. For the printing process the gold or silver particles are bound in a special solution and applied to the glass extremely finely in a digital procedure. In the tempering process that follows the valuable metal bonds permanently to the glass.

In order to protect the printed design from environmental influences and mechanical damage such as scratches, the printed side is placed on the inside of the laminate towards the film interlayer and is thus protected by the glass. “After three years of research and development we have now extended the spectrum of our digital printing to include the possibility to design glass panes with the majestic shine of real gold and silver – even in oversized formats”, Ulrich Theisen, Sales Manager at sedak, is pleased to report. “There is a fascinating interaction between the transparency of the glass and the brilliance of the precious metals, which captivates the observer.” Sedak uses the glass panes printed with genuine precious metals to produce insulating and security glass, including curved glass.

Digital printing: fast, flexible, creative

Digital printing of precious metals offers numerous advantages compared with other procedures. Whereas with coating only full-surface application of the metal layer is possible, with digital printing even the most intricate designs can be printed: fine dots, complex patterns and even color gradients can be achieved. There are hardly any limits to creativity: “The digital gold and silver printing can also be combined with ceramic color printing”, explained Theisen. A further advantage of digital printing is the economical application of the material – a cost advantage, especially with precious metals.

Gold and silver are timeless classics and exude luxurious radiance as optical highlights. Extravagant concepts for interiors and façades can be realized with the high-quality materials. Sedak’s new printing technique will be used for the first time in a large project in Asia.

With a digital printing process, sedak prints panes

of up to 3.30 x 18 meters with real gold and silver.

Photo: sedak

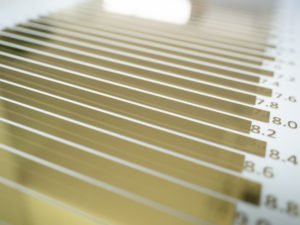

Shining results: precious metal printing allows even

complex designs and filigree details to be realized –

with a resolution of up to 1024 dpi.

Photo: sedak

Unlimited creativity: the printed glass can be processed

further into insulating and safety glass, and can even be curved.

Photo: sedak

Richly adorned: the precious metal print in gold and silver

is processed into a laminate and is thus protected from

mechanical influences, keeping its characteristic shine.

Photo: sedak

For more information please contact:

| sedak GmbH & Co. KG Tatjana Vinkovic Tel.: +49(0)821/2494-823 Fax: +49(0)821/2494-777 E-Mail: tatjana.vinkovic@sedak.com |

|||

Reprint free of charge, copy requested

Leading glass

sedak, the glass manufacturer in Gersthofen, Germany, was founded in 2007. The company and its 170 employees have developed into the world’s technology and innovation leader for large insulating and safety glass. With a ten-year experience of manufacturing oversize glass and after having increased the level of automation continuously, sedak is regarded as a specialist in this know-how intensive segment. The glass units reach dimensions up to 3.51 m x 20 m – processed, tempered, laminated, printed, coated, and cold bent. The core capabilities are the lamination of glass, edging, and the company’s special knowledge of producing glass components with additional functional and decorative elements. sedak’s production has been optimized for extraordinary glass sizes and weights; all finishing steps are highly automated and handled in-house. As a full supplier for glass up to 20 m, sedak sees itself as a partner for architects, designers, and façade constructors. Outstanding references are for example the House of European History in Brussels, the Faculty of Medicine in Montpellier, the Torre Europa in Madrid, Brookfield Place in New York City, the United Nations Office at Geneva, the Apple Cube in New York City, the science center experimenta in Heilbronn, as well as numerous premium flagship stores worldwide.

Applications

- glass façades

- glass roofs

- glass stairs

- glass balustrades

- ship building

- safety glazing

- all-glass constructions

- interior design

- custum-made glass units