sedak presents 18-layer laminate at glasstec special show

Laminated safety glass in new dimensions: With 18 layers and a total thickness of about 30cm, sedak presents the world’s thickest-ever laminate at the special show “glass technology live”. It is an outstanding example for the dimensions the glass expert is able to laminate. Thus, they also expand the possibilities for the material as a supporting element for structural glazing. The exhibit shall inspire architects’ and designers’ imagination and open up new space for creativity. From this year’s September, sedak produces the biggest insulating and safety glass with dimensions of 3.51m x 20m; the second glass record sedak currently holds.

To produce oversize glass for the use as a responsible supporting structure is standard at sedak. Glass fins and beams from Gersthofen (Bavaria) are used worldwide as supporting elements for all-glass façades or roofs. Designers create thus, archetypal buildings with the transparent material that have become landmarks. The House of European History in Brussels is an example for that as well as the medical faculty in Montpellier, or a gigantic mall in Bangkok.

The exhibit at the special show is a laminate out of 18 layers, each one 15mm thick, bonded with SentryGlass interlayer. The about 30cm thick laminated safety glass weighs 3.6 tons. Every single glass pane has a breaking strength of at least 160 MPA. “The physical characteristics of this extreme glass build-up allow for completely new ways in the construction with glass,” says Ulrich Theisen, General Manager at sedak, and emphasizes the significance of the in-house development. Such glass constructions resist highest pressure loads and keep their transparency at the same time since the 18 Optiwhite glass layers do not reduce the view through the laminate. Thanks to sedak’s lamination art, the heavy-weight is free from bubbles or other interfering contaminations.

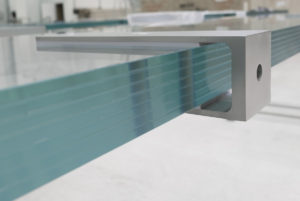

At the stand of sedak’s partner Benteler (hall 15, E 11), the glass manufacturer additionally showcases a glass-fin exhibit as a part of a construction of an all-glass façade. The filigree connection of glass fin and façade glazing via toggles is technologically pioneering. Those especially small titanium parts unite maximum transparency with an installation-friendly glazing system. They are integrated precisely into the multiple laminate by sedak.

Special show at glasstec: glasstechnology live with sedak’s 18-layer laminate in hall 11.

Glass fin by sedak: Stand Benteler, hall 15, stand E 11.

Eighteen single glass panes, one exhibit, the highest level

of transparency, and perfect workmanship: sedak presents lamination

art of superlatives at the special show „glass technology live“.

Photo: sedak GmbH & Co. KG

Glass fins with 5- to 10-layer glass build-ups in sedak’s

production. They are used for all-glass facades,

representative foyers, or extensive all-glass roofs.

Photo: sedak GmbH & Co. KG

To ensure a quick and safe installation of the glass fins

at the construction site, the elements receive metal parts at

sedak’s production that are provided by the client.

Photo: sedak GmbH & Co. KG

Packed safely: The 17-meter long glass

beams are transported to the construction

site in custom-made boxes.

Photo: sedak GmbH & Co. KG

For more information please contact:

| sedak GmbH & Co. KG Tatjana Vinkovic Tel.: +49(0)821/2494-823 Fax: +49(0)821/2494-777 E-Mail: tatjana.vinkovic@sedak.com |

|||

Reprint free of charge, copy requested

Leading glass

sedak, the glass manufacturer in Gersthofen, Germany, was founded in 2007. The company and its 150 employees have developed into the world’s technology and innovation leader for large insulating and safety glass. With a ten-year experience of manufacturing oversize glass and after having increased the level of automation continuously, sedak is regarded as a specialist in this know-how intensive segment. The glass units reach dimensions up to 3.2 m x 16.5 m – processed, tempered, laminated, printed, coated, and cold bent. The core capabilities are the lamination of glass, edging, and the company’s special knowledge of producing glass components with additional functional and decorative elements. sedak’s production has been optimized for extraordinary glass sizes and weights; all finishing steps are highly automated and handled in-house. As a full supplier for glass up to 16.5 m, sedak sees itself as a partner for architects, designers, and façade constructors. Outstanding references are for example the House of European History in Brussels, the Faculty of Medicine in Montpellier, the Torre Europa in Madrid, Brookfield Place in New York City, the United Nations Office at Geneva, the Apple Cube in New York City, the science center experimenta in Heilbronn, as well as numerous premium flagship stores worldwide.

Applications

- glass façades

- glass roofs

- glass stairs

- glass balustrades

- ship building

- safety glazing

- all-glass constructions

- interior design

- custum-made glass units