Artwork on 51 glass units

A complex, ceramic-ink digital print on 51 glass units transforms the new building of the internationally active learning institution “Cambridge Assessment” into a spectacular landmark. It is based on a question by the artist couple Vong Phaophanit and Claire Oboussier: What is knowledge? sedak (Germany) printed the numerous answers, which the artists received in many languages, on 36 double laminates up to 4 m x 2.45 m and 15 IGUs up to 4.58 m x 1.98 m. The result is a strong statement for the transnational and intercultural character of the non-profit education institution, and also for sedak’s glass competence. At night, the saffron orange glass units of the 39-meter high tower shine like a lighthouse to the world. The units of indigo and grey shades support the metaphorical level of the connecting link between the two building complexes.

Cambridge Assessment, a department of the University of Cambridge, provides education programs in more than 170 countries and develops the basis of knowledge transfer. To be able to keep doing that efficiently in the future, the planning of the Triangle Project started in 2013. Enough space for 3,000 employees, meeting rooms, modular and customizable space for e.g. a kindergarten, and a variety of outdoor spaces are supposed to safeguard the chance to evolve for the current growth course of the non-profit organization.

Visible for miles around: profile of a definition of knowledge

Eric Parry Architects and HLM Architects decided to use a “Site responsive Artwork” to make the core of Cambridge Assessment visibly tangible for miles around. For the realization, they worked together with the artists Phaophanit and Oboussier (London). The cooperation focused on the question how the world interprets “knowledge” multilingually and regardless of time. Besides current statements from all over the world, the artists also considered the definitions they found on old parchment papers and papyri. Out of that collection, they created the piece of art “IN OTHER WORDS” consisting of two parts of ceramic-ink print works. One is for the façade of the so called “link” connecting the two main building complexes, and the second one is for the top of the 39m high central tower.

In close cooperation with the creatives, sedak put their art on glass. “We met technically very affine and curious partners who had great interest in what is possible and how our capabilities can be integrated into the artwork,” says Ralf Scheurer, sedak’s project manager.

Ceramic-ink printing with experience, competence and daring

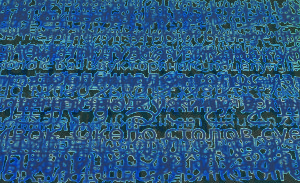

The artists merged the countless definitions into one absolutely overwhelming mix. Words and letters of different sizes and languages blur and intertwine smoothly forming a massive front of words. From afar, it seems like a shimmering color composition. However, from a close distance, the lines are well legible due to the precise digital print. The artists had a particular idea of the right Pantone color shades and their detailed gradation, and therefore great demands on the inks. By means of several 300mm x 400mm glass samples, the right nuances were defined in close cooperation with sedak. The “link” is designed with shades of indigo and grey leading to strong associations to science, whereas the tower’s top reminds of a lighthouse, illuminated at night, shining in saffron orange to the distance. “The artists enthusiastically involved into the technical process and took interactions for their work out of it. We share the love for perfection. Therefore such a meaningful piece of art arouse,” says Scheurer.

Technically demanding printing

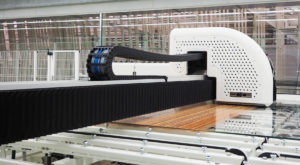

sedak used the ceramic-ink digital printer to finish the 476 sqm of glass according to the artists‘ concept. Printed with a resolution of 1024dpi, also the fine lines of the Arabic and the Far East languages were applied pin sharp to the glass. The smallest letters are only 6mm high. The UV- and scratch-resistant ceramic inks guarantee a long-term brilliance of the art. Thanks to meticulous edging, and lamination with free glass edges, sedak assured a high glass quality that met the demands of the elite university.

Two characteristic elements and the material glass make the new building of Cambridge Assessment a landmark. Together with the tower, the backlit glass façade out of orange-colored laminates form an architectural accent that is visible for miles around. The blue printed IGUs of the Skywalk link two wings and are a visual counterpart of the tower.

Photo: sedak GmbH & Co. KG

After sunset, the 36 laminates of the backlit facade, which were printed elaborately, shine like a lighthouse to the distance.

Photo: sedak GmbH & Co. KG

Precision work: The smallest letters are only six millimeters high. For the artwork, the answers to the question “What is knowledge?” were collected and printed on glass in their original language.

Photo: sedak GmbH & Co. KG

Precision work: The smallest letters are only six millimeters high. For the artwork, the answers to the question “What is knowledge?” were collected and printed on glass in their original language.

Photo: sedak GmbH & Co. KG

sedak printed the glass units during with a highly precise technique that ensures a long-term quality. The printer reaches up to 1024 dpi.

Photo: sedak GmbH & Co. KG

The glass artwork “In Other Words“ is high up on the top of the central tower of Cambridge Assessment.

Photo: sedak GmbH & Co. KG

For more information please contact:

| sedak GmbH & Co. KG Tatjana Vinkovic Tel.: +49(0)821/2494-823 Fax: +49(0)821/2494-777 E-Mail: tatjana.vinkovic@sedak.com |

|||

Reprint free of charge, copy requested

sedak GmbH & Co. KG

Leading glass

sedak, the glass manufacturer in Gersthofen, Germany, was founded in 2007. The company and its 150 employees have developed into the world’s technology and innovation leader for large insulating and safety glass. With a ten-year experience of manufacturing oversize glass and after having increased the level of automation continuously, sedak is regarded as a specialist in this know-how intensive segment. The glass units reach dimensions up to 3.2 m x 16.5 m – processed, tempered, laminated, printed, coated, and cold bent. The core capabilities are the lamination of glass, edging, and the company’s special knowledge of producing glass components with additional functional and decorative elements. sedak’s production has been optimized for extraordinary glass sizes and weights; all finishing steps are highly automated and handled in-house. As a full supplier for glass up to 16.5 m, sedak sees itself as a partner for architects, designers, and façade constructors. Outstanding references are for example the House of European History in Brussels, the Faculty of Medicine in Montpellier, the Torre Europa in Madrid, Brookfield Place in New York City, the United Nations Office at Geneva, the Apple Cube in New York City, the science center experimenta in Heilbronn, as well as numerous premium flagship stores worldwide.

Applications

- glass façades

- glass roofs

- glass stairs

- glass balustrades

- ship building

- safety glazing

- all-glass constructions

- interior design

- custum-made glass units